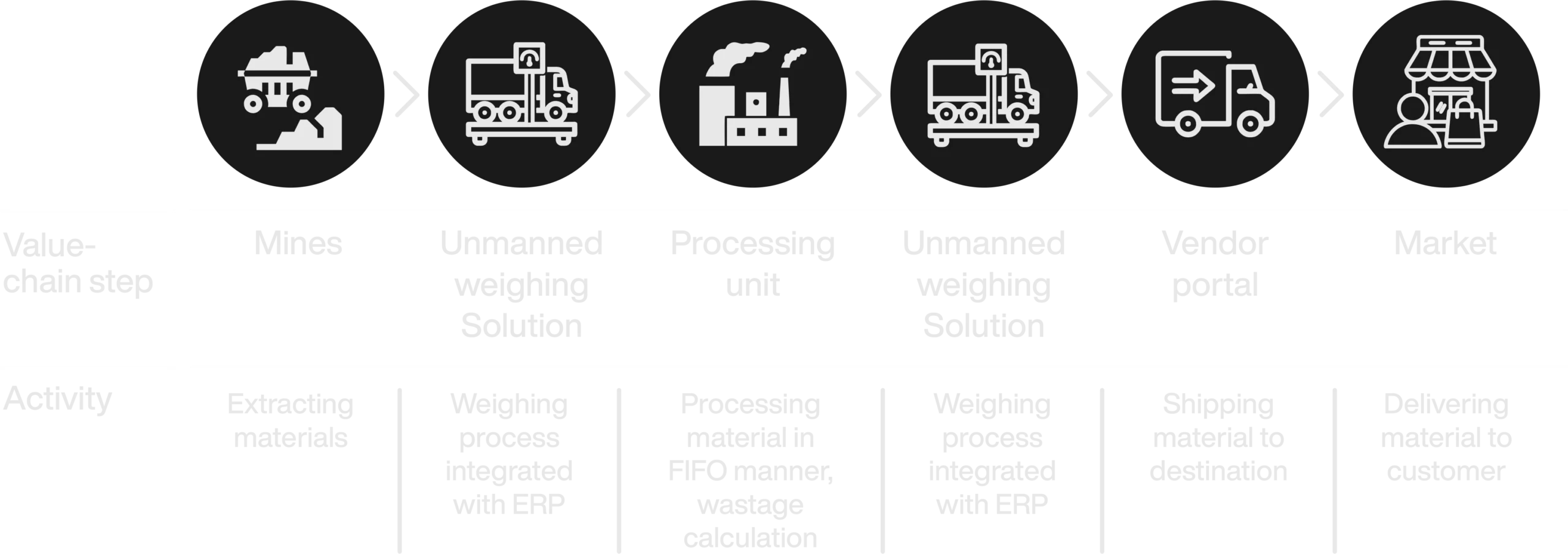

Digitizing Mining Operations with Unmanned Weighbridge Integration & ERP Connectivity

A leading mining and power generation company undertook a strategic transformation to digitize its end-to-end mining logistics and weighing processes. The challenge centered around managing silo-based loading/unloading activities scattered across a vast mining zone and the inability to accurately track and validate vehicle movements. To address this, a comprehensive mining automation solution was deployed—integrating multiple weighbridges, ANPR, RFID, and SAP for a fully unmanned, seamless operation. The result was greater operational transparency, cycle time optimization, and complete elimination of manual dependency.

Solution Overview

To address the complex logistical and operational challenges of silo-based mining dispatch, a comprehensive unmanned weighbridge system was implemented. This solution digitized the entire vehicle movement and weighment process, removing the need for manual intervention and enabling seamless, real-time operations across all dispatch points.

All 5 to 6 weighbridges, regardless of their original OEM or platform, were integrated into a centralized control system. This eliminated the issues caused by fragmented data and manual reconciliation. Each vehicle is now identified using RFID tags, and its entry and exit are tracked using ANPR (Automatic Number Plate Recognition) cameras installed at critical checkpoints. These systems work together to ensure that only authorized vehicles pass through and that each step — from loading to final weighment — is digitally validated.

In addition, the system was tightly integrated with SAP/ERP, enabling real-time synchronization of weighment data, job orders, and material movement records. This not only improved traceability and inventory accuracy but also enhanced billing and audit processes downstream.

Deployment Scope

The solution was deployed across the organization’s full mining zone, including:

- All silo locations and weighbridge stations within the 2–3 km operational radius.

- Both inbound (raw material loading) and outbound (finished material dispatch) traffic flows.

- A central control room interface from which logistics teams, plant supervisors, and inventory managers can monitor, validate, and report activities in real time.

This comprehensive coverage ensured consistent automation across every point in the logistics chain — removing silos (figuratively and literally) from the process.

Unmanned Weighbridge Workflow

The reimagined weighbridge flow follows a fully automated and auditable path:

Key features of the solution:

Vehicle Entry at Silo Zone

Vehicles enter through any silo gate; RFID readers and ANPR cameras instantly validate vehicle identity against system records.

Initial Weighment

The vehicle proceeds to an available unmanned weighbridge for the first weight capture (gross or tare). The system detects the vehicle, logs the weight, and pushes the data to ERP.

Loading/Unloading at Silo

Guided by the RFID tag, the vehicle reaches the designated silo where material handling occurs — linked automatically to the correct job order.

Second Weighment

After loading/unloading, the vehicle visits any weighbridge for the final weight (tare or gross). The system calculates net weight and updates the ERP without any manual input.

Exit Validation

Before leaving the mining zone, final RFID and ANPR checks are performed. Only after all workflow steps are validated, the gate opens, and the transaction is digitally closed.

Results & Business Impact

This transformation delivered both operational efficiency and strategic control:

- 100% automation of vehicle validation and weighment, eliminating human error and operator involvement entirely.

- Faster turnaround times, with reduced cycle delays at silos and weighbridges.

- Full visibility into vehicle movement and job progress through real-time dashboards.

- Seamless ERP integration provided accurate, on-time data for billing, inventory tracking, and compliance documentation.

- Greater security and traceability, with every action logged and auditable.

- The company now operates with improved confidence, better compliance, and a model scalable across additional sites — setting a new benchmark for digital mining logistics.

Before this system, we had no way of knowing how many vehicles were inside, which silo they were headed to, or whether the data in ERP was even accurate. Now everything’s automated — the weighbridges work without any manual input, and we can see all movements live. It’s made our operations faster, cleaner, and much more reliable.