How Digitization Revolutionized Cement Supply Chains

Vendor to Payment Automation

Opening the Supply Chain: How a Leading Cement Manufacturer Transformed Vendor, Dispatch, and Payment Operations with Digital Integration

A major Ugandan cement manufacturer and ex-member of the Holcim Group, operates multiple plants and quarries across East Africa. Despite its large-scale output, the company faced growing challenges managing a complex supply chain of vendors, dispatches, orders, and payment flows.

“There were too many manual touchpoints in our supply chain. Vendors didn’t have visibility. Orders got delayed. Payments were held up due to process gaps. It was time to digitize the core.”

– Head of Supply Chain

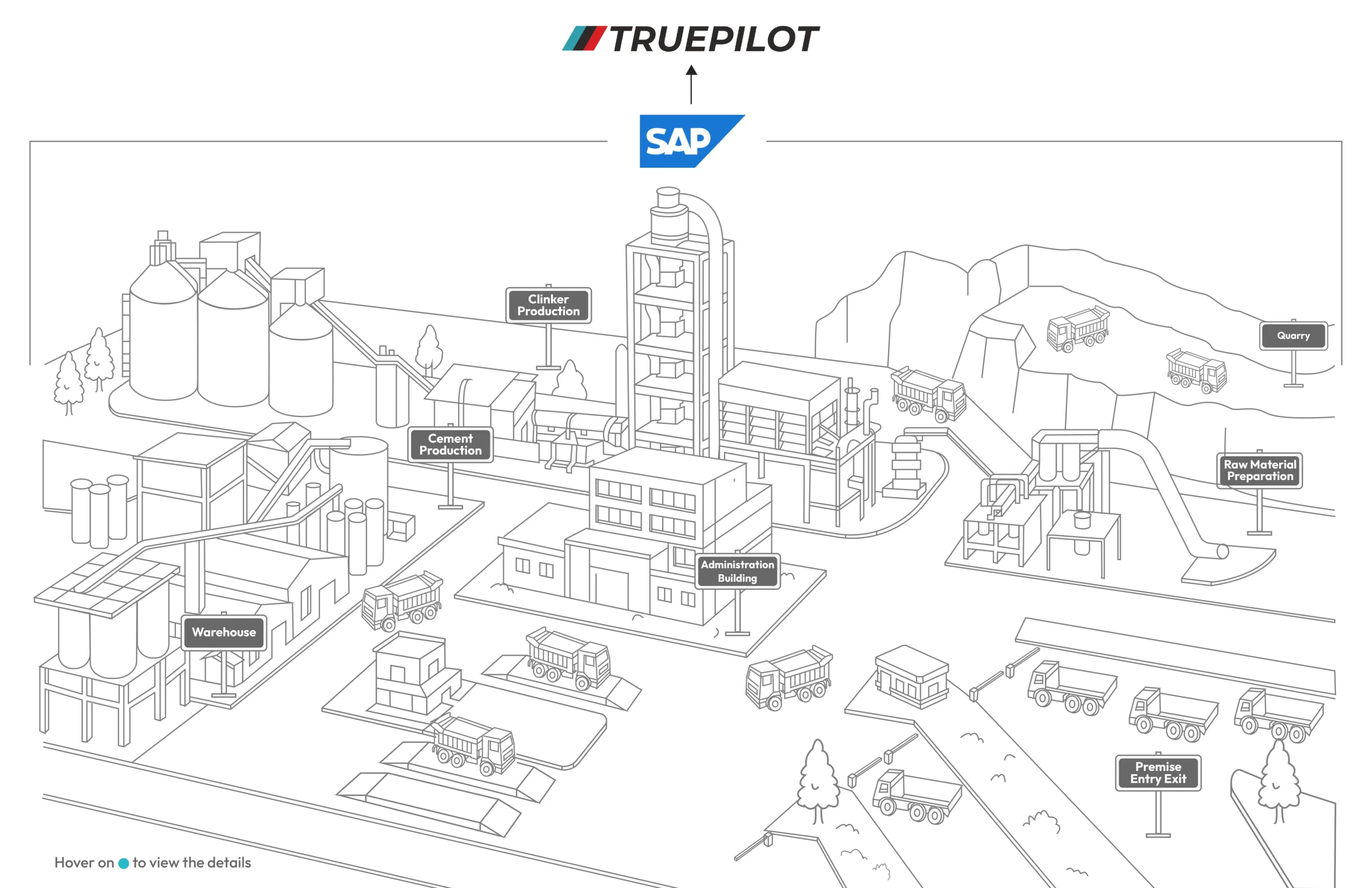

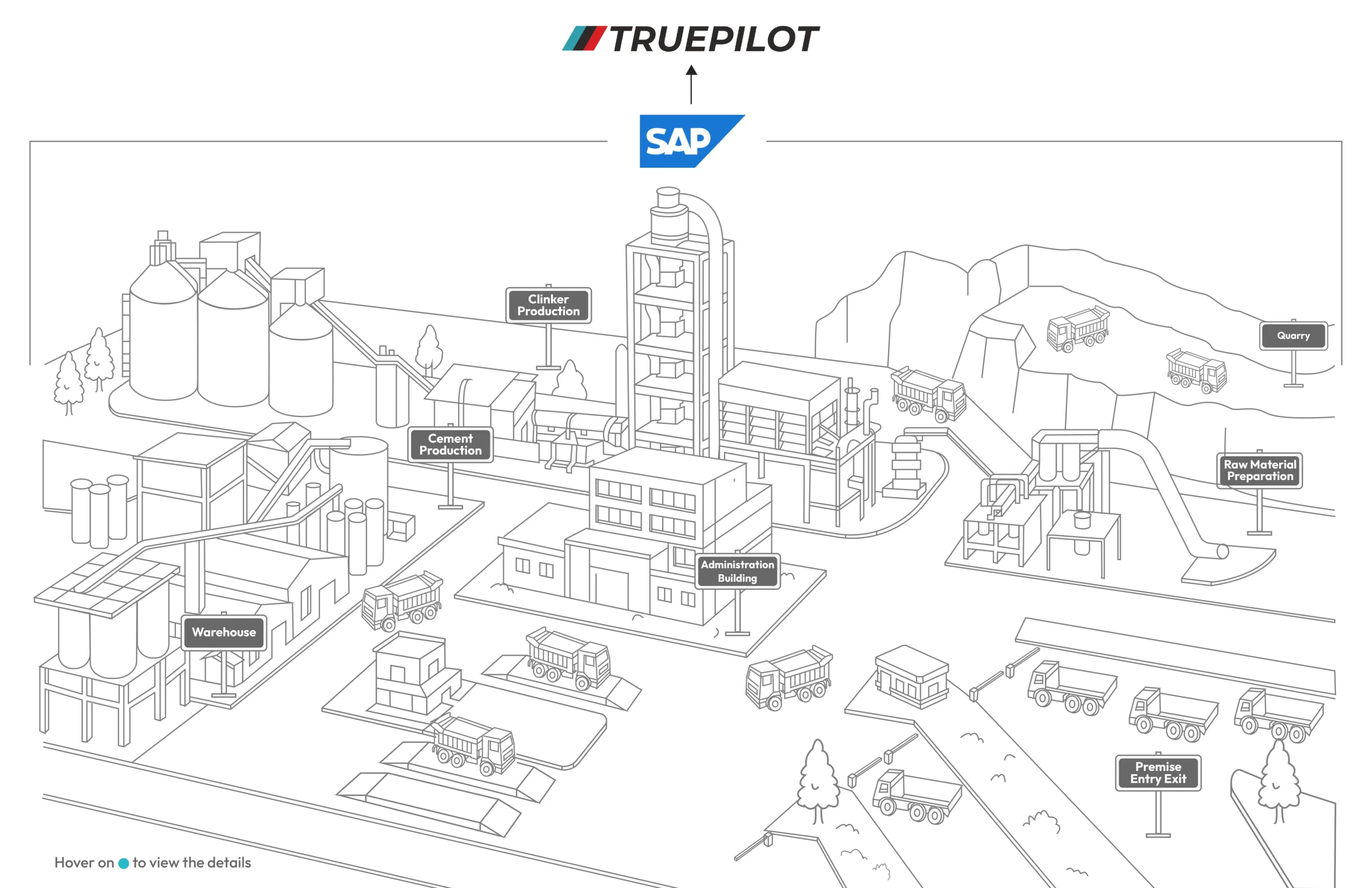

Weighbridge Automation

A complete unmanned operation featuring automated access control, sensor-based vehicle positioning, kiosk-enabled slip printing, error-free weighment, and real-time ERP integration.

Gate Management System

An automated access control system integrated with RFID and ANPR ensures complete data accuracy, enhanced vehicle profiling for security, and provides detailed logs and reports.

Parking Queue Management Inspection

An automated access control system that enables real-time recording of vehicle arrival and departure times, monitors turnaround time, and helps in theft prevention.

Area Restriction

Limiting access to specific zones, allowing only authorized personnel or vehicles through controlled, automated systems for safety and security.

Loading and Unloading

Involve controlled transfer of materials using automated systems for speed, accuracy, and safety.

Dispatch Management System

Streamlines the planning, tracking, and execution of deliveries to ensure timely and accurate dispatch of goods.

Integration for real-time data sync, ensuring accurate tracking, seamless operations, and centralized control across the system.

A complete Plant Information Management System, enabling end-to-end automation, real-time data visibility, and centralized operational control.

Weighbridge Automation

A complete unmanned operation featuring automated access control, sensor-based vehicle positioning, kiosk-enabled slip printing, error-free weighment, and real-time ERP integration.

Gate Management System

An automated access control system integrated with RFID and ANPR ensures complete data accuracy, enhanced vehicle profiling for security, and provides detailed logs and reports.

Parking Queue Management Inspection

An automated access control system that enables real-time recording of vehicle arrival and departure times, monitors turnaround time, and helps in theft prevention.

Area Restriction

Limiting access to specific zones, allowing only authorized personnel or vehicles through controlled, automated systems for safety and security.

Loading and Unloading

Involve controlled transfer of materials using automated systems for speed, accuracy, and safety.

Dispatch Management System

Streamlines the planning, tracking, and execution of deliveries to ensure timely and accurate dispatch of goods.

Integration for real-time data sync, ensuring accurate tracking, seamless operations, and centralized control across the system.

A complete Plant Information Management System, enabling end-to-end automation, real-time data visibility, and centralized operational control.

The Problem: A Disconnected and Delayed Supply Chain

At the heart of manufacturer’s issues was a fragmented supply chain system. While cement production was streamlined, everything around vendor management, dispatch scheduling, order processing, and payment tracking relied on spreadsheets, calls, and siloed data.

Key challenges included:

- Manual vendor coordination with no real-time order tracking

- Delays in dispatches due to lack of truck scheduling or queue visibility

- Payment delays caused by mismatched weighment and invoice data

- Limited visibility across departments and plants for tracking supply chain performance

- Weighbridge operations and gate entries that were disconnected from the ERP

The result : frequent miscommunication, inefficient processing, compliance issues, and low vendor satisfaction.

The Solution: End-to-End Supply Chain Digitization

To fix the root of the problem, organization partnered with Endel Digital to deploy a connected, automated solution—centered around its supply chain.

Key features of the solution:

Vendor & Supply Chain Portal:

Vendors can place orders, track dispatches, view payment status, and monitor delivery progress—all in one place.

Automated Dispatch & Gate Management:

Smart queueing, vehicle access control, and zone restriction ensure secure and organized truck movement across plants.

Weighbridge Integration with SAP:

Real-time, unmanned weighments sync directly with SAP to prevent manual entry errors and enable timely invoicing.

Digital Checklists & SOP Validation:

Vehicle inspections and material validations are systemized and tracked digitally.

Live Dashboard (TruePILOT):

Full visibility into order status, vendor performance, delivery milestones, and pending payments across all levels.

“This gave us control over what was once chaotic. We can now manage vendors, track trucks, and sync payments—all from a single dashboard.”

– SCM Transformation Lead

Results: Streamlined Supply Chain and Smarter Vendor Operations

Since implementation, organization has realized significant improvements across key metrics:

Faster Vendor Payments

Real-time data syncing ensures quicker invoice processing and reduced disputes.

70% Reduction in Dispatch Delays

Truck movement is now scheduled and monitored digitally.

Full Supply Chain Visibility

From order to dispatch to payment, every stakeholder has access to live updates.

Reduction in Manual Processes

Digital checklists, automated weighment, and ERP sync reduce paperwork and manual entry.

Improved Vendor Experience

Vendors now operate with clarity—less follow-up, more trust, and full transparency.

100% Process Compliance

Automated controls ensure every production step meets quality & safety standards without deviation.

“We used to work reactively. Now, our supply chain is proactive. The system alerts us before there’s a problem.”

– Head of Plant Logistics

Scaling Forward: Building a Predictive Supply Chain

Encouraged by the transformation, the organization is expanding the system’s reach with:

- Multi-site vendor coordination

- Predictive truck dispatch planning

- Vendor rating and performance dashboards

- Self-service mobile interface for vendors and transporters

“This digitization has become the foundation for smarter supply chain planning. It's helped us build a future-ready operation.”