Powering the Future of Cement through Smart Digitalization The cement industry, a pillar of global infrastructure, is at a turning […]

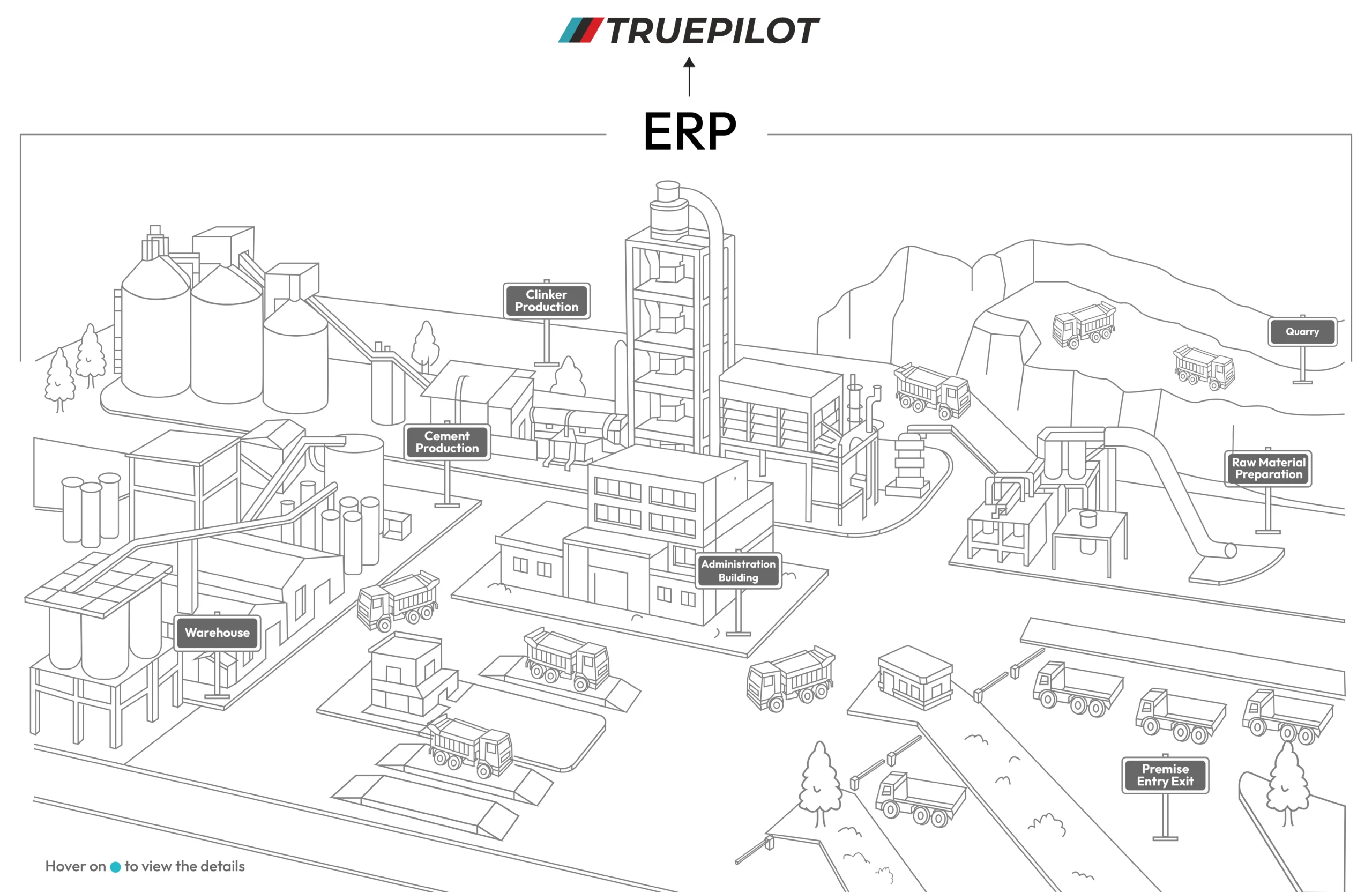

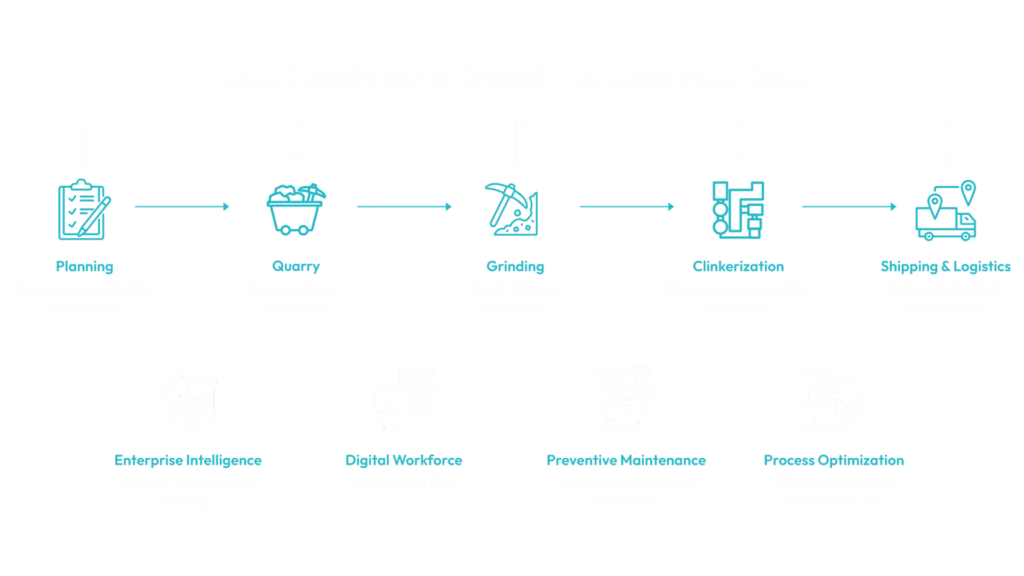

From Quarry To Dispatch

We combine deep operational knowledge with specialized technical expertise to deliver comprehensive production optimization solutions for cement plants.

Challenges been faced:

- Raw material headaches (inconsistent quality, moisture variations, blending difficulties)

- Equipment wear from abrasive materials (kiln tire cracks, mill liner wear, conveyor belt degradation)

- High-dust environment challenges (sensor failures, maintenance difficulties, safety risks)

- Process bottlenecks (kiln feed fluctuations, cooler inefficiencies, grinding circuit imbalances)

Our Offerings

Weighbridge Automation System

Digitized Material Testing

Complete Production Process Digitization

Cloud-Based Supply Chain Management

Secure Premise Management System

Weighbridge Automation

A complete unmanned operation featuring automated access control, sensor-based vehicle positioning, kiosk-enabled slip printing, error-free weighment, and real-time ERP integration.

Gate Management System

An automated access control system integrated with RFID and ANPR ensures complete data accuracy, enhanced vehicle profiling for security, and provides detailed logs and reports.

Parking Queue Management Inspection

An automated access control system that enables real-time recording of vehicle arrival and departure times, monitors turnaround time, and helps in theft prevention.

Area Restriction

Limiting access to specific zones, allowing only authorized personnel or vehicles through controlled, automated systems for safety and security.

Loading and Unloading

Involve controlled transfer of materials using automated systems for speed, accuracy, and safety.

Dispatch Management System

Streamlines the planning, tracking, and execution of deliveries to ensure timely and accurate dispatch of goods.

Integration for real-time data sync, ensuring accurate tracking, seamless operations, and centralized control across the system.

A complete Plant Information Management System, enabling end-to-end automation, real-time data visibility, and centralized operational control.

Testing Lab

Ensures material quality by conducting precise chemical and physical tests on raw materials, clinker, and cement.

Production visibility

Real-time monitoring of each stage—right from raw material handling to clinker production and final cement dispatch—enabling better control, faster decision-making, and improved operational efficiency

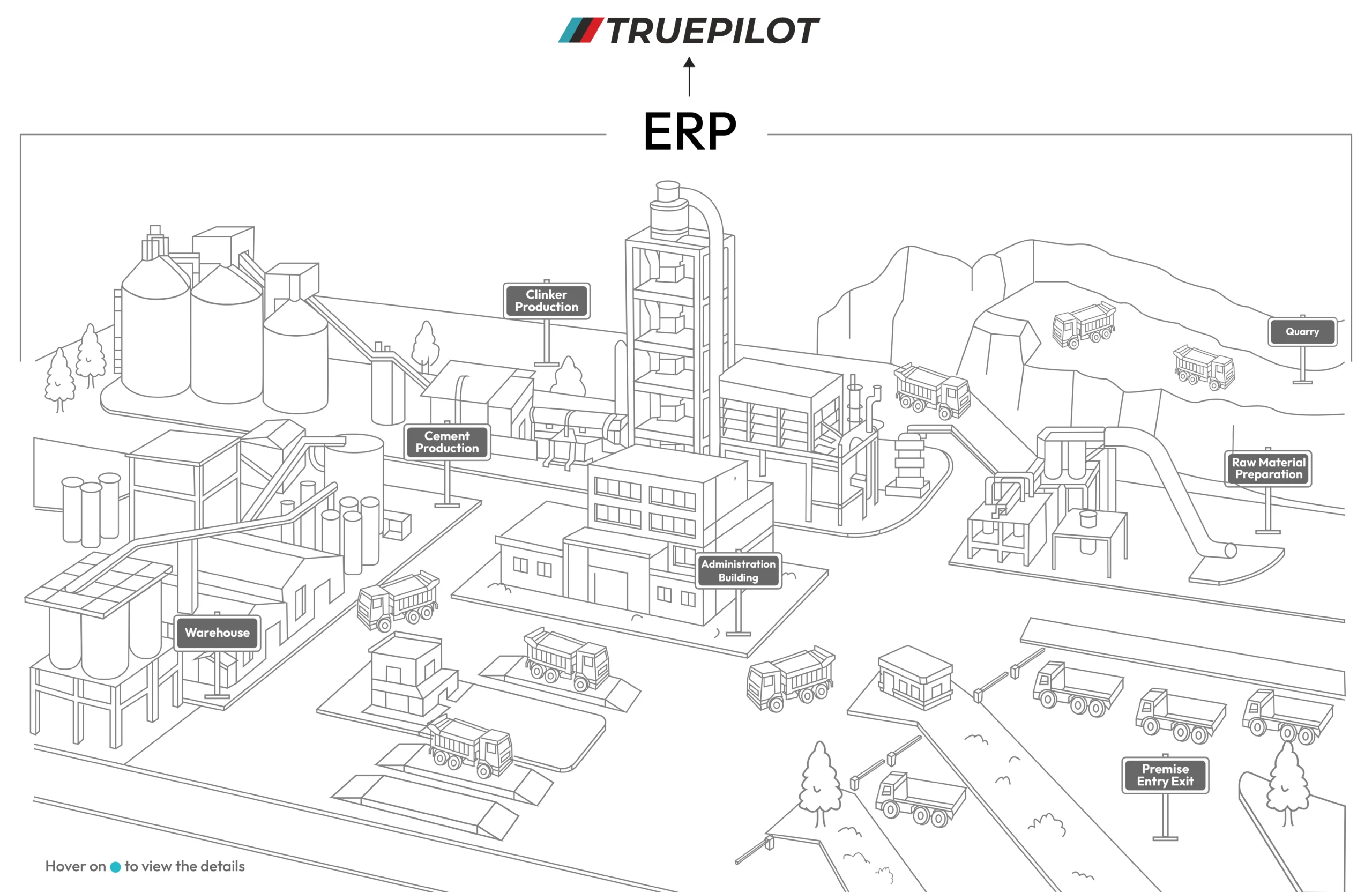

Schematic diagram of Production Plant

Weighbridge Automation

A complete unmanned operation featuring automated access control, sensor-based vehicle positioning, kiosk-enabled slip printing, error-free weighment, and real-time ERP integration.

Gate Management System

An automated access control system integrated with RFID and ANPR ensures complete data accuracy, enhanced vehicle profiling for security, and provides detailed logs and reports.

Parking Queue Management Inspection

An automated access control system that enables real-time recording of vehicle arrival and departure times, monitors turnaround time, and helps in theft prevention.

Area Restriction

Limiting access to specific zones, allowing only authorized personnel or vehicles through controlled, automated systems for safety and security.

Loading and Unloading

Involve controlled transfer of materials using automated systems for speed, accuracy, and safety.

Dispatch Management System

Streamlines the planning, tracking, and execution of deliveries to ensure timely and accurate dispatch of goods.

Integration for real-time data sync, ensuring accurate tracking, seamless operations, and centralized control across the system.

A complete Plant Information Management System, enabling end-to-end automation, real-time data visibility, and centralized operational control.

Production visibility

Real-time monitoring of each stage—right from raw material handling to clinker production and final cement dispatch—enabling better control, faster decision-making, and improved operational efficiency

Schematic diagram of Production Plant

Gate Management System (GMS):

Smart entry/exit system using RFID and ANPR for secure access, precise vehicle identification, and comprehensive audit trails.

Weighbridge Automation:

Fully automated weighment process with zero manual intervention, ensuring accurate readings, seamless ERP integration, and faster throughput.

Parking & Queue Management with Inspection:

Tracks vehicle movement in real time, manages parking sequence, logs inspection digitally, and prevents unauthorized access or delays.

Parking & Queue Management with Inspection:

Tracks vehicle movement in real time, manages parking sequence, logs inspection digitally, and prevents unauthorized access or delays.

Area Restriction Control:

Enforces access limits to critical plant zones using automated validation, enhancing operational safety and regulatory compliance.

Loading & Unloading Automation:

Streamlined material handling using automated tools for precise, fast, and safe loading or unloading of goods.

Highlights

How Digitization Revolutionized Cement Supply Chains Vendor to Payment Automation Contact Us Download the Whitepaper Opening the Supply Chain: How […]

Concrete Success: How Endel Digital paved the way for digital transformation at RDC Concrete Our client’s business operations run 24/7 […]